It took me by surprise recently when LinkedIn told me I’d been at Accelerando for two years. It really has been that long since I decided I was done working at somebody else’s dream job, and ventured into the great self-employed adventure where a small-business owner can work whichever 24 hours a day they choose.

After a period of working as a distributed team and from various coworking spaces, we have now been in our Sumner Park lab for 15 Months, and grown to a staff of six (plus a number of specialists who work with us at need).

Our lab and event space gives us the resources to construct almost anything, from a simple sensor to an autonomous robot. We chose the name Accelerando to highlight agility; we aim to get your project from a standing start to full speed as fast as possible. To do this we manaintain the resources to assemble a proof-of-concept IoT device in as little as a day, without waiting for part shipping. Once we attain rapid validation from a proof-of-concept, we incorporate lessons learned then design and deliver professional prototypes, and if you wish we can take you all the way to volume manufacturing.

Let’s look at some of the things we’ve done in the last year.

The projects

Some of the projects to which we contributed in 2018 include:

-

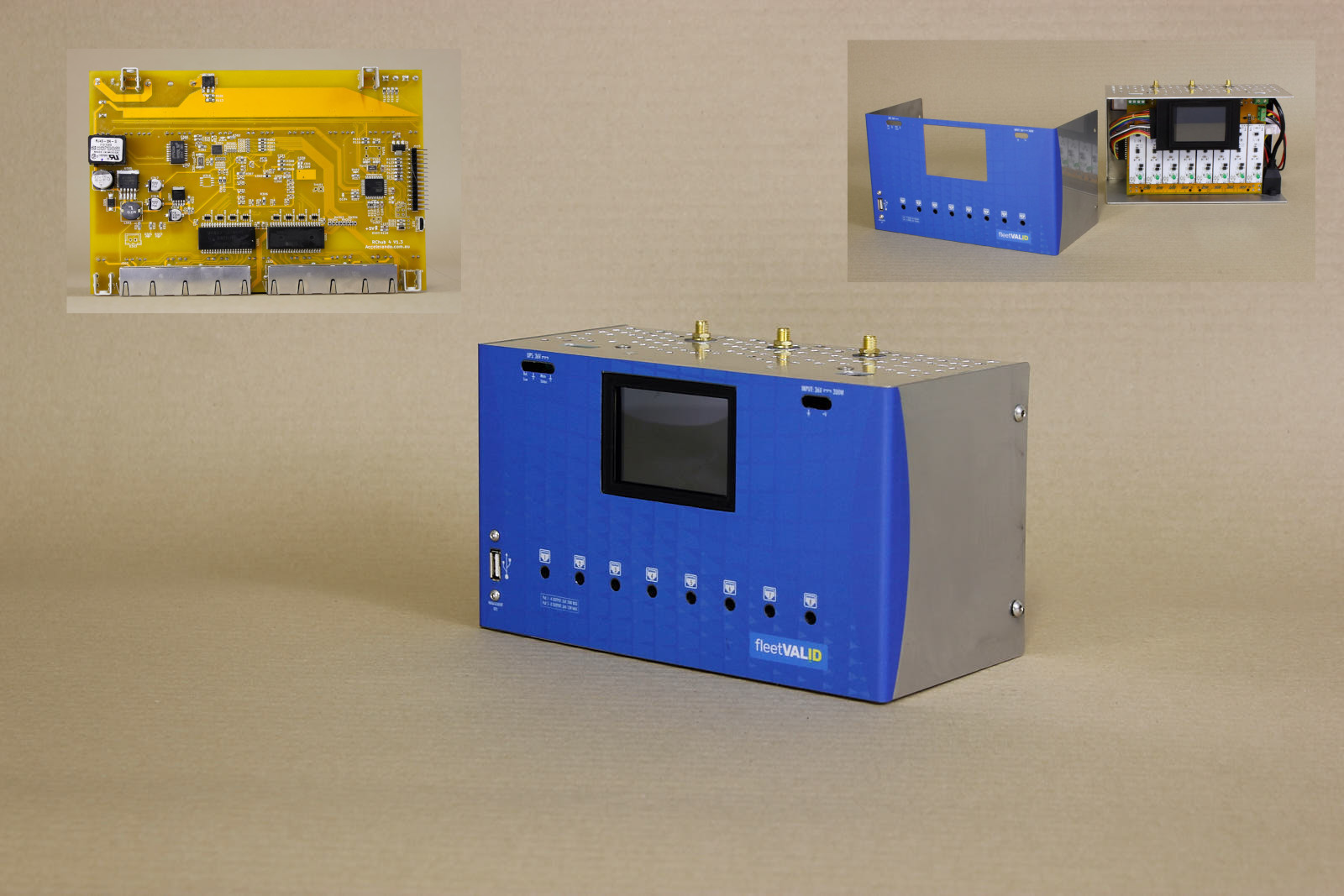

An equipment tracking system for emergency vehicles utilising UHF radio tags for rapid inventory confirmation.

-

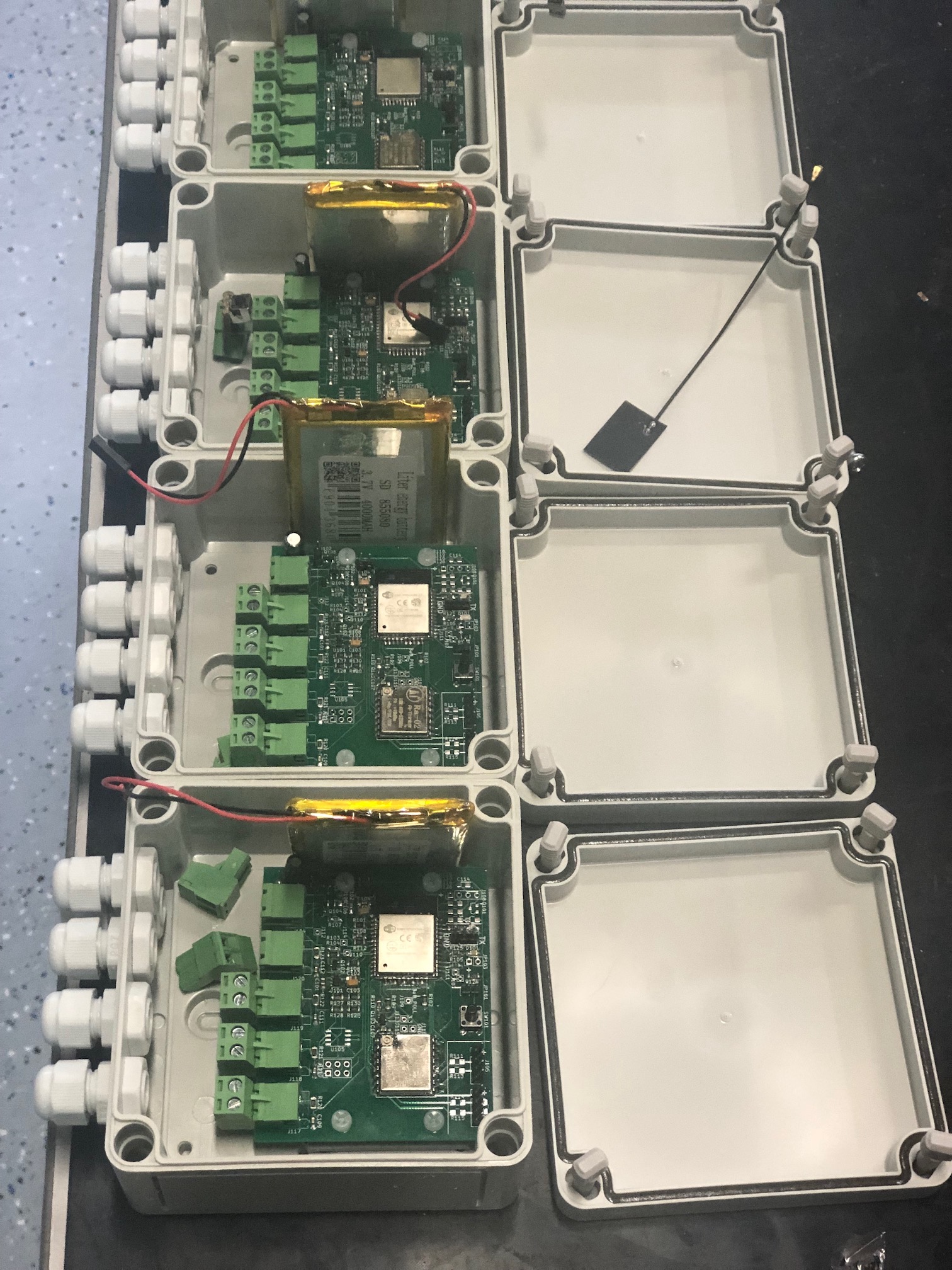

A command-and-control system for under-road traffic counting sensors

-

Smart meter retrofit for mechanical water meters, consisting of sensor platform, site uplink, and cloud data lake.

-

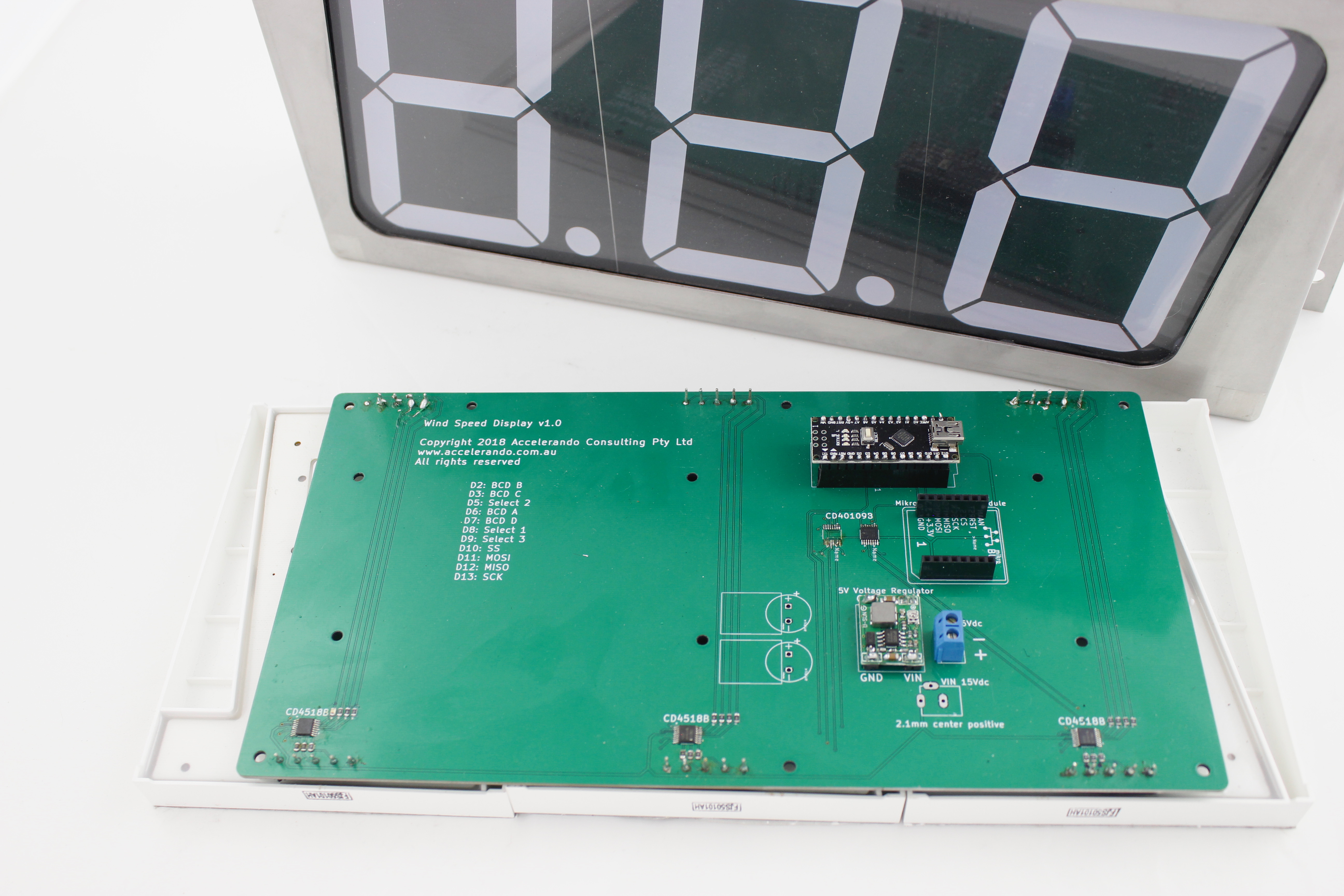

Digital Wind speed displays for a new RAAF hangar

The space

Our workshop also hosted the Brisbane Internet of Things Interest Group practical workshops in 2018, bringing members of the group together to make smart clothing, assemble 3D printers, create IoT weather sensors, and more.

Our new AV Studio lets us do anything from a close-up “product glamour shot” to an instructional video.

We prototype with 3D printing, light laser cutting, sheet metal, milling and machining on site, and our network of specialists nearby add printing, plastics, heavy duty lasercutting and fabrication.